Eco-friendly Products and Technologies

Eco-friendly Business Expansion Strategy

Eco-friendly Products and Technologies Strengthening Policy

Today, as the impact of climate change grows, companies are becoming more environmentally responsible. Coway is actively introducing eco-friendly technologies to minimize the environmental impact of its products and to realize its goal of Net-Zero. Coway is working to develop eco-friendly products and technologies based on the 3 strategies below.

Market Leadership

Innovative products

Regulation Adaptation

Eco-friendly products

Developing innovative technologies and products to proactively address ESG-related regulations

Securing New Growth Engines

Market leadership

Eco-friendly Certification in 2023

Coway obtained Eco-Label certification for ‘4 types of BEREX mattresses’ in 2023. The Eco-Label system is a voluntary certification system that requires eco-friendly products that can reduce the consumption of energy and resources and minimize the generation of pollutants throughout each stage of the entire process of products and services ― including production, distribution, use, and disposal ― to have a distinct logo (environmental label) with a short description. Coway has been recognized for its environmental performance in the categories of reducing hazardous substances, reducing everyday environment pollutants (mattresses), energy saving, reducing local environmental pollution, reducing hazardous substances (bidets), and reducing noise and vibration (purifiers); and as of 2023, Coway has 30 Eco-Label certifications. In addition, all product lines, including environmental home appliances such as water purifiers, air purifiers, and bidets, as well as mattresses and massage chairs, were selected as '2023 Inno Star and Green Star.' Inno Star and Green Star are a certification system in which consumers directly evaluate a company's awareness of eco-friendly products and are certified by the Korea Management Certification Board. In particular, the Prime Stand Water Purifier utilizes energy-saving technology to achieve an energy-consumption efficiency rating of 1. By applying 'multi-sensing and inverter technology' that monitors internal and external temperatures in real time and automatically adjusts the amount of electricity according to usage conditions, we have reduced annual electricity bills by about 20% compared to existing products.

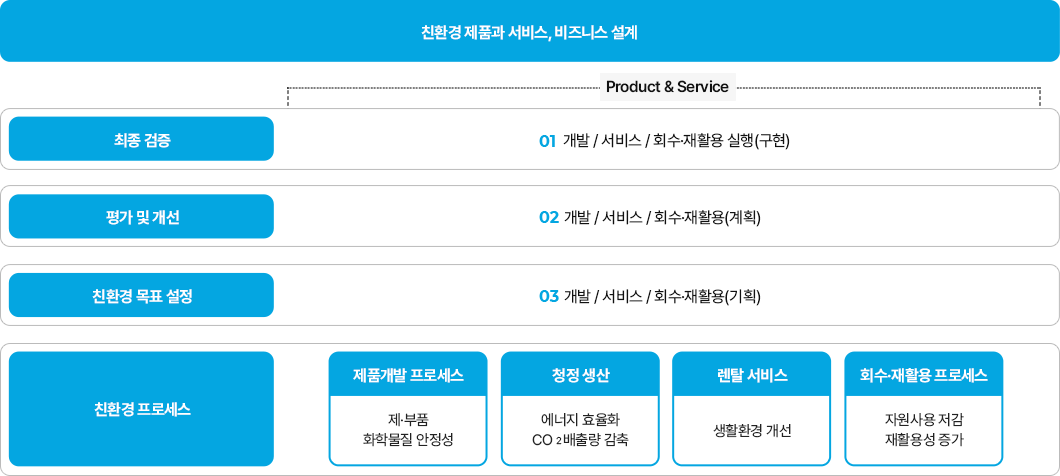

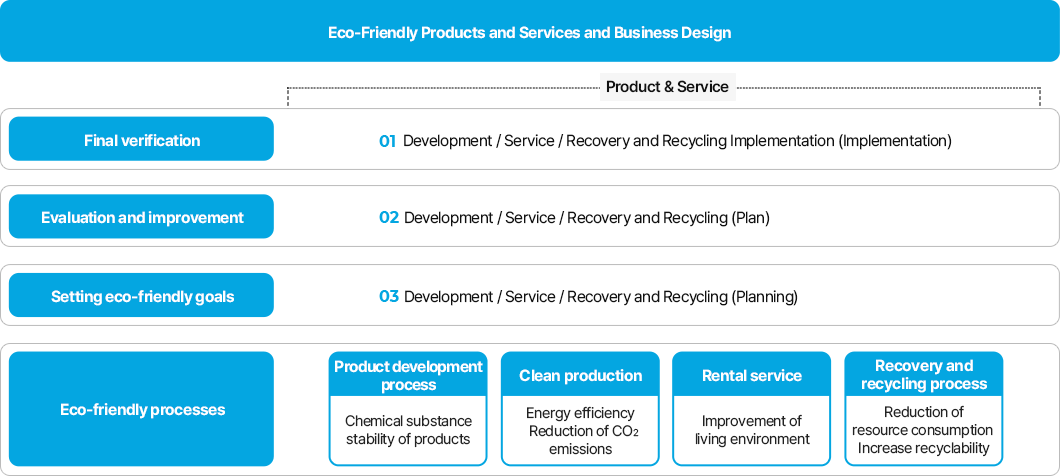

Eco-friendly Product Design

Eco-friendly Product Design Process

Development of Eco-Friendly Products and Technologies

The strategy for developing eco-friendly products and technologies is led by the Technology Strategy Team of Coway's Environmental Technology Research Institute, and other departments in the working group are responsible for implementing tasks in response to related risks and opportunities. We report project performance and plans 4 times a year through the ESG Council.

Bidets

We are the only company in Korea to use recycled materials (recycled PCR resin) that are flame-retardant, and we are applying recycled materials (recycled PCR resin) at least 10% of the weight of plastic for five bidet products from 2023.

Purifiers

WINNER purifiers use 99% recycled materials in the design and implementation of their exteriors, and some of the filters that are inserted into the purifiers were made for easier discharge and recycling. This was the first time in Korea to implement resource recycling technology in the field of filters manufacturing exclusively for purifiers. As such, Coway is minimizing waste generation by developing and expanding the application of PLA-based biodegradable air matching filter fabric and single-material dust collecting filters, which are easy to separate and recycle.

Mattresses

Prime Mattress uses Recycled Polyester Fiber (RPE) from REGEN, which has obtained GRS (Global Recycling Standard), an international eco-friendly certification standard, for its mattress covers, and promotes ESG management by reducing carbon emissions during the production process.

Air Cell Cushions

Air Cell is a thin vinyl structure that is inflated with air to provide the same level of cushioning as traditional Styrofoam (EPS), while maintaining the same shipping quality, but shrinking the volume by up to 1/120th to maximize logistics innovation. In addition, it has the advantage of improving the packaging production and disposal as it does not generate dust or residue and is easy to separate and dispose of. Coway has been using eco-friendly Air Cell cushions in its product and component packaging. Air Cell was applied to water purifier pumps and sterilizers in 2022, and to bidets BAS31-A and BAS-41 in 2023, reducing packaging volume to 1/40th of EPS. It was also applied to the packaging of large purifiers, reducing the volume by 28% compared to Styrofoam (EPS) packaging and 46% compared to cartons, contributing to the reduction of carbon emissions through logistics efficiency.

Resource Circulation

Resource Circulation Management System

To realize resource circulation, Coway considers environmental factors throughout all product stages (LCA, Life Cycle Assessment), from development and purchase to recovery and recycling. In accordance with the Act on Resource Circulation of Electrical and Electronic Products and Automobiles, we have established and operated a waste resource recovery and recycling system to comply with relevant laws and regulations. Through these activities, Coway plans to continue its efforts to improve resource efficiency and achieve zero waste with the goal of achieving a 100% waste- resource recovery rate and a 100% recycling rate of waste generated at its business sites by 2030.

Resource Circulation Process

Development and purchase

- Use of more circulated materials

- Designing eco-friendly products and achieving the energy consumption efficiency rate 1

- Purchasing raw materials verified for chemical safety

Manufacturing

- Business site waste-resource recovery (SRF, solidified fuel)

- Expanding production of refurbished models

- Utilizing new and renewable energy such as solar power

Distribution

- Advancement of reverse logistics system

- Application of eco-friendly packaging materials (eco-friendly pulp material packaging, Air Cell cushions)

- Minimize the use of resources with lighter packaging

Application

- Improving energy efficiency by applying an instantaneous hot water system and a high-efficiency inverter cold water system

- Driving the purchase of eco-certified products

Repair and reuse

- Enabling refurbished product sales

Recovery and recycling

- Recycle and reuse more waste products and filter materials

- More recovered and recycled items

- Advancement of recovery and recycling operations

Waste Recycling Rate Targets

Coway's goal is to achieve a 100% recycling rate of recyclable wastes and 100% resource-recovery rate of waste from business sites by 2030. In particular, by maintaining the refurbished product system, which was introduced for the first time in the home appliance rental industry in 2007, until today, Coway has established a sustainable management system throughout the entire value chain that internally reduces disposal costs and externally satisfies eco-aware consumers. This goal will become Coway's environmental management achievement that will be accomplished before it achieves Net-Zero in 2050.

Waste Recycling Performance and Targets

Establishment/operation

of circular economy system in 2023

Target waste-recycling

rate by 2030

Target business site

waste-recycling rate by 2030

Product Life Cycle Management

When developing new products, Coway ensures that each product meets a recycling rate of 75% or higher. If it is calculated at 75% or less, we work to increase the recycling rate by product line by switching to recyclable materials or looking closely at additional recycling opportunities in the process.

Waste-Product Recovery and Recycling

Coway has established and consistently implemented a recovery and recycling policy to minimize the environmental impact of its products. In addition, we are setting an example as a leading company in the industry through voluntary participation in government-promoted projects. In particular, Coway introduced the *Refurbishment System for the first time in the rental home appliance industry in 2007. Parts that need to be replaced can be replaced with new parts, thoroughly tested for quality/performance to ensure they are as good as new, while reducing the environmental burden of disposal. Through this system, we internally reduce rental disposal costs and externally continue to create value by operating price-competitive products and contributing to the resource circulation economy.

* Refurbishment system: A system that reprocesses products that have been returned or displayed in stores due to consumer change of mind and sells them at reasonable prices.

Participation in Voluntary Agreement on Recovery and Recycling of Waste Mattresses

Coway has been operating a waste-mattress resource circulation process since 2018 to minimize the environmental impact of discarded waste mattresses. Coway directly operates and manages the entire process of collecting mattresses used and discarded by customers including △warehousing them to logistics centers △warehousing them to specialized recycling companies with Coway-specific recycling systems △cutting and shredding △separating valuable materials (scrap metal, synthetic resin) and △management of waste resource processors. The Ministry of Environment recommended our mattress recovery and recycling system as a representative example of waste mattress resource circulation, and a voluntary agreement was reached in the process of encouraging other mattress companies to establish recycling processes. Coway will continue to lead the way in building a circular economy as a leading mattress rental company.

Use of More Circulated Materials

Coway is participating in the recycling usability evaluation system to expand the application of recycled raw materials (recycled PCR resin). The Circularity Assessment System is a system that recommends improvements to design factors that make it difficult for products to be recycled when they become waste, and discloses relevant facts if they are not implemented. On December 29, 2023, Coway received a certificate of conformity from the Ministry of Environment (MOE) for applying 10% of the plastic weight of 5 bidet models as recycled raw materials (recycled PCR resin). 2 additional models have since been certified, bringing the total to 7 products certified for the Circular Assessment.

Status of Application of Recycled Materials by Bidet Model

| Category | BA20-D | BAS25-A | BAS29-C | BASH30-A | BAS31-A | BAS36-A | BAS40-A |

|---|---|---|---|---|---|---|---|

| Applicable parts | 3 parts | 5 parts | 4 parts | 4 parts | 6 parts | 5 parts | 5 parts |

| Total weight of plastic (g per unit) |

2,961 | 3,026 | 3,151 | 3,383 | 3,174 | 3,238 | 2,971 |

| *Total weight of recycled plastic (g per unit) | 304 | 314 | 323 | 362 | 329 | 385 | 301 |

| Rate of application | 10.26% | 10.38% | 10.24% | 10.70% | 10.38% | 11.88% | 10.15% |

* 50% PCR applied to recycled plastic

Based on Article 19 of the Framework Act on Resource Circulation, ‘Circular Assessment’, water purifier products and massage chair products have been newly included in the products subject to Circular Assessment. Accordingly, Coway is planning to pilot apply recycled raw materials (recycled PCR resin) to its water purifier product line in order to comply with the Framework Act on Resource Circulation.

Eco-friendly design and packaging

Coway is committed to the eco-friendly use of materials and energy in production, and develops products with eco-friendly design and recycling considerations for production, use, and disposal. We are also implementing green technologies and energy-saving systems to help us operate in an economically efficient way, while minimizing our environmental impact.

Eco-friendly Paper Water Purifier Wins CES 2023 Innovation Award

Coway won the President's Award at the 2023 Korea Packaging Daejeon for its eco-friendly Paper Water Purifier. This is an up-cycling concept that also won the Innovation Award at CES 2023. The Coway Paper Water Purifier has been made usable by assembling previously discarded product packaging materials into the exterior case of the water purifier. In addition, the internal parts were modularized into a single material without assembly screws to facilitate separate disposal, and the resource circulation rate was increased by using eco-friendly paper packaging even for the product packaging cushioning material.