- Environmental /

- Waste and Resource Circulation

Coway has been striving to increase recycling, achieve zero waste, and minimize production costs through quantitative waste management. In particular, for waste generated in our business sites and service areas, we are making efforts to reduce waste to zero through the sale of used goods and treatment of solid refuse fuel (SRF), and we are contributing to the reduction of resource use by developing products using secondary raw materials made through resource circulation.

Through these activities, we plan to improve resource efficiency and work toward zero waste, with the goal of achieving a rate of 100% of waste recycling and a rate of 100% of reusing waste generated at our plants by 2030.

Coway takes the environment seriously throughout the entire product life cycle, from development and purchase to collection to recycling, in an effort to move toward a more resource-efficient and circular economy. We will step up our efforts to go green and minimize the inevitable environmental impacts of business activities with our top-notch technological process.

Coway monitors the recycling rate per product to determine if it reaches 75 percent or more when developing a new product. In cases where the recycling rate is estimated to be below 75 percent, we will replace the materials to renewable materials or carefully seek ways to increase the rate of recycling per product.

In 2022, Coway applied recycled raw materials (recycled PCR resin) to its bidet product lineup at a rate of 5% of the product's plastic weight, and in 2023, Coway is expanding the use of recycled raw materials (recycled PCR resin) to make up 10% of the product's plastic weight for five bidet models. In 2023, the water purifier product line was newly included as a product line subject to circular utilization evaluation based on Article 19 of the Resource Circulation Basic Act. To that extent, Coway is planning to pilot the application of circular raw materials (recycled PCR resin) in the water purifier product line.

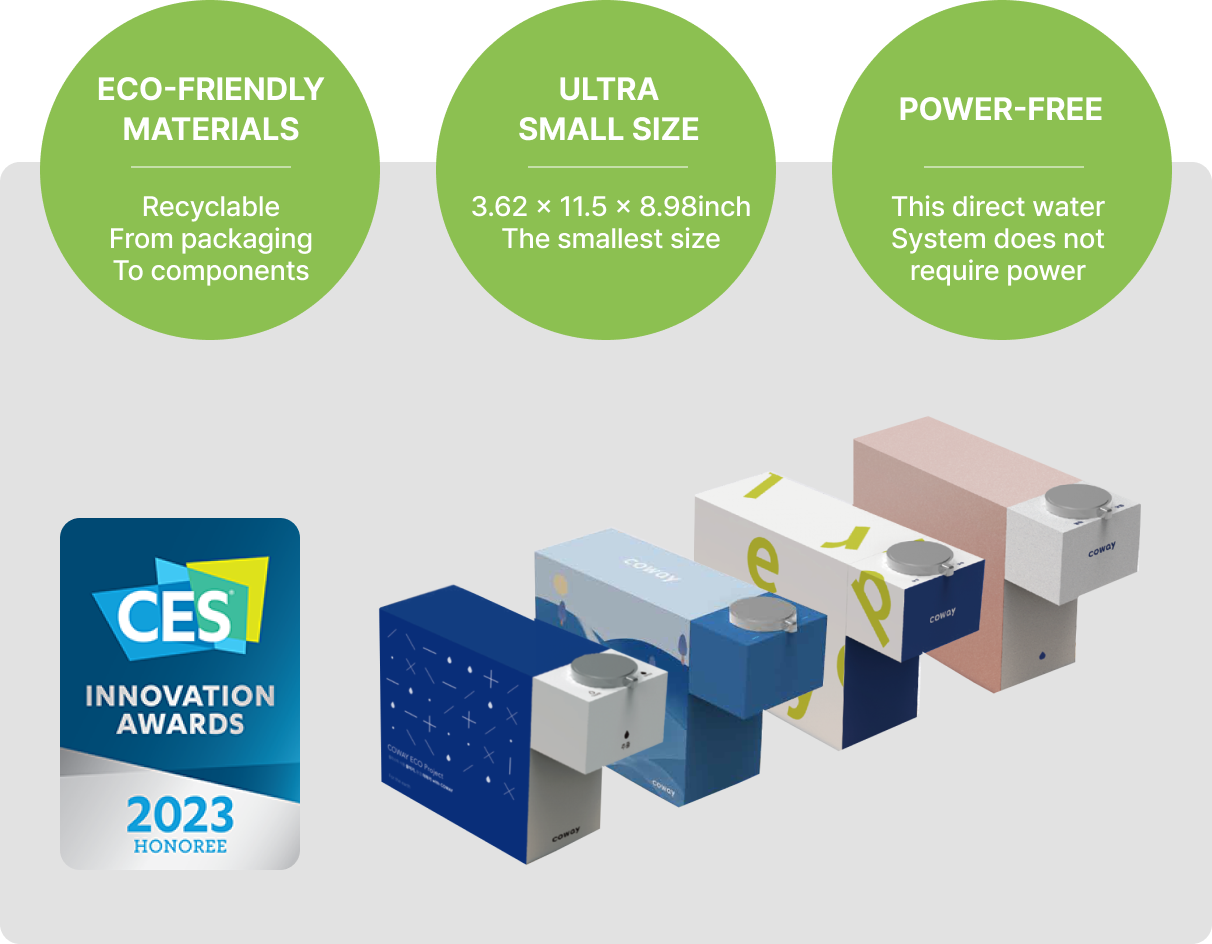

In addition, Coway continuously explores eco-friendly design and packaging methods to innovate product design and save resources. For example, we design the exterior of our products with eco-friendly paper instead of plastic, and we design packaging so that the packaging and packaging materials can be upcycled. In this way, Coway will continue to strive to reduce resources (by increasing recycling rates, expanding the use of recycled raw materials, and applying eco-friendly designs and packaging).

Model

BA20-D

BAS25-A

BAS29-C

BASH30-A

BAS31-A

Applicable Parts

3 Types

5 Types

4 Types

4 Types

6 Types

Total Weight of Injection

2,961

3,026

3,151

3,383

3,174

Weight of the recycled materials

304

314

323

362

329

Recycled Resin Application Rate per Part

10.26%

10.38%

10.24%

10.70%

10.38%

Green Design Example

The “Eco-friendly Paper Water Purifier” was recognized for its innovation in that the exterior of the product is made of eco-friendly paper instead of plastic. In addition, the product's eco-friendliness was enhanced by making all packaging materials and packaging accessories upcyclable. Coway's eco-friendly paper water purifier is economical as it does not use electricity, and its ultra-compact size makes it easy to install in small spaces such as in single-person households and studios.

The products in the final stage of the life cycle are collected for the efficient recycling process. The collected items are vast, ranging from product packaging materials to consumables, bulk waste, and disused products. We pick up disused products for free through our own take-back process and divide them into industrial waste and disused products to transform them into solid recovered fuels (SRFs) or recyclables. In 2022, Coway improved the recycling rate and reduced costs (waste disposal charges, disposal costs, etc.) by improving waste treatment methods for waste generated at some of its plants.

Coway contributes to the circular economy and meets its environmental responsibilities by recycling waste products and services, consumables and packaging materials, and waste from company sites in accordance to its own recovery and recycling processes. In particular, due to recent increases in the sales of self-managed products, Coway is recovering and recycling waste filters generated in this process.

As the number of customers using self-managed products increases, we are expanding our filter collection service in various ways.

At the end of 2021, Coway implemented a “home delivery collection service” for used water filters for customers who use self-care products, and at the end of 2022, Coway encouraged customers to participate in collection and recycling activities by providing information on the “separate disposal of recyclable plastics” if they do not want home delivery.

During the first year of service, nearly 260,000 sets of self-care filters were collected. The collected filters are separated, pulverized, and repurposed into new products such as toolboxes and car bumpers.

From 2022, replacement water filters will be included in the Extended Producer Responsibility (EPR) and will be required to comply with recycling obligations. Coway has been building and operating a circular economy system in line with national policies and will continue to expand its operating model to contribute towards improving recovery and recycling rates.

Year

December, 2021

2022

2023 (Prediction)

Number of products recovered

1,533 sets (3,066)

(3,066개)

257,683 sets

(515,366)

202,612 sets

(405,224)

We continue reducing the use of refrigerants in order to minimize environmental pollution. We also collect refrigerant (R-134a) that was used for some old products to have them treated safely by the relevant service providers designated by the Ministry of Environment.

Refurbishment refers to the process of processing products that have been returned because consumers change their minds about them or products that were on display in stores and reselling them at reasonable prices. The refurbished products are as good as new as we replace parts with new ones when necessary and conduct rigorous quality testing, which reduces waste treatment and consequently reduces environmental impact.

In 2007, we became the first home appliances rental service provider to introduce the refurbishment program. Since then, we have been reducing disused rental products internally and creating value through a supply of cost-competitive products and practicing contributing to the circular economy, externally.

Performance in 2022: 5,374 units (water purifiers, purifiers, bidets, mattresses)

Target for 2023: 2,000 units (forecasted volume based on discontinuation of existing operating models and the launch of new refurbished products in the second half of the year)